Introduction:

Investing in a blast cabinet is a significant decision for businesses involved in surface preparation and finishing tasks· Whether you are in manufacturing, automotive restoration, or any industry that requires efficient abrasive blasting, choosing the right blast cabinet is crucial for optimal performance and cost-effectiveness· In this blog post, we will explore the ten essential factors you must consider before buying a blast cabinet to ensure that your investment aligns with your specific needs and requirements·

Type of Abrasive Material:

Different blasting cabinets are designed to work with specific abrasive materials, such as sand, glass beads, or aluminum oxide· Understanding the type of abrasive material you will be using is crucial, as it affects the cabinet’s design, construction, and compatibility·

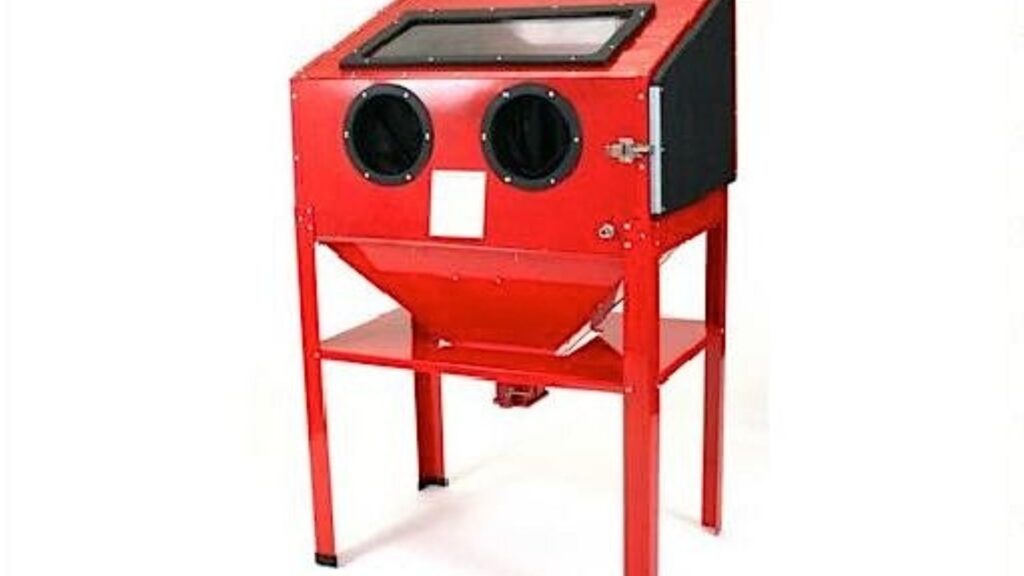

Size and Dimensions:

The size of the blast cabinet should accommodate the size of the parts or products you intend to blast· Consider the dimensions of the cabinet’s workspace, entrance openings, and overall footprint to ensure it meets your operational requirements·

Dust Collection System:

Efficient dust collection is vital for maintaining a clean and safe working environment· Evaluate the blast cabinet’s dust collection system, including the type of filter, its capacity, and the ease of maintenance· A robust dust collection system contributes to better visibility and operator safety·

Cabinet Construction Material:

The durability of the blast cabinet depends on its construction material· Cabinets made from heavy-duty materials like steel or fiberglass are preferable for longevity and resistance to abrasive wear· Ensure that the construction material aligns with the type of abrasive material you will be using·

Workpiece Handling Features:

Consider the features that facilitate easy loading and unloading of workpieces· Features like turntables, carts, or adjustable shelving can enhance the efficiency of your blasting operations and accommodate a variety of workpiece sizes and shapes·

Glove Ports and View Windows:

Glove ports and view windows are critical for operator comfort and control during blasting· Check the quality and size of glove ports, as well as the visibility provided by view windows, to ensure that operators can work effectively and monitor the blasting process·

Blast Gun and Nozzle Design:

Evaluate the blast gun and nozzle design for efficiency and durability· Adjustable nozzles and guns with ergonomic features enhance control and precision during abrasive blasting· Consider the ease of maintenance and the availability of replacement parts·

Air Compressor Requirements:

Understand the air compressor requirements of the blast cabinet· Ensure that your existing air compressor meets the specifications or be prepared to invest in an appropriately sized compressor for optimal performance·

Accessibility for Maintenance:

Regular maintenance is essential for the longevity and performance of a blast cabinet· Choose a model that provides easy accessibility to internal components for routine maintenance tasks like replacing filters, checking hoses, and inspecting abrasive media levels·

Budget and Cost of Ownership:

While upfront costs are a consideration, it’s essential to assess the long-term cost of ownership· Factor in maintenance, energy consumption, and potential upgrades· A well-built blast cabinet with higher upfront costs may offer better value over time through reliability and reduced maintenance expenses·

Conclusion:

Before purchasing a blast cabinet, it’s crucial to thoroughly assess your specific operational needs and the features offered by different models· By considering factors such as abrasive material compatibility, size, dust collection, construction material, workpiece handling features, operator comfort, blast gun design, air compressor requirements, accessibility for maintenance, and the overall cost of ownership, you can make an informed decision that aligns with your blasting requirements and ensures a productive and efficient surface preparation process·