Adhesion testing is an essential process in determining the strength of bonding between a coating and the substrate it covers. It is crucial in industries such as construction, manufacturing, and automotive, where coatings protect materials from corrosion, wear, and other environmental impacts. To achieve accurate results with an adhesion tester, proper surface preparation is critical. In this blog, we will explore the importance of surface preparation in adhesion testing and why it can significantly impact the test results.

Why Surface Preparation is Crucial

The success of an adhesion tester relies on the quality of the surface it is applied to. If the surface is not prepared correctly, it can compromise the accuracy of the test results, leading to incorrect conclusions about the coating’s performance. Surface preparation is the process of cleaning, roughening, or treating the surface before the test to ensure that the adhesion tester provides a true measure of bond strength.

Contaminants like dirt, grease, oils, or oxidation layers can hinder proper adhesion between the coating and the substrate. If these contaminants remain on the surface during the test, they can create weak points that reduce the coating’s overall bond strength, resulting in false or skewed data from the adhesion tester.

Types of Surface Preparation

There are various methods of surface preparation that are commonly used before conducting adhesion tests. The method you choose depends on the type of substrate and coating, as well as the environment in which the coating is applied. Some of the most common methods include:

1. Cleaning

Cleaning is the first step in surface preparation, and it involves removing any dust, oils, dirt, or residues that may have accumulated on the substrate. Solvents or chemical cleaners are often used to wipe the surface clean and prepare it for testing with an adhesion tester. Without thorough cleaning, even small particles or residues can significantly reduce adhesion strength.

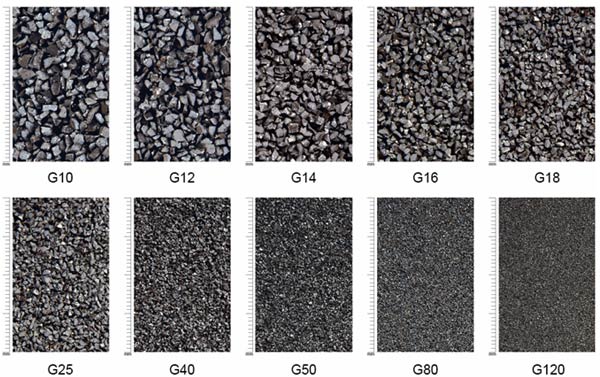

2. Mechanical Abrasion

Abrasion techniques, such as sandblasting or using abrasive pads, are used to roughen the surface of the substrate. This method creates a textured surface that allows the coating to grip the substrate better, improving adhesion. Mechanical abrasion is particularly important when dealing with smooth surfaces like metals, where roughening can improve the reliability of the adhesion tester results.

3. Chemical Etching

Chemical etching is another surface preparation method where acids or other chemical agents are applied to the substrate to clean and roughen it. This method is often used on materials like glass or ceramics, where mechanical abrasion may not be suitable. Chemical etching can help increase surface energy, thereby improving the performance of the adhesion tester.

The Impact of Poor Surface Preparation

If surface preparation is neglected, even the best adhesion tester cannot provide reliable results. Poor surface preparation can lead to weak bonds, and the test may indicate that the coating has failed, even when it has the potential to perform well under proper conditions. For instance, contaminants like oil or dust can prevent the coating from bonding effectively to the substrate, creating an artificial weak spot. This, in turn, leads to inaccurate readings when using the adhesion tester.

Additionally, improper preparation can result in peeling or delamination that may not reflect the actual performance of the coating in a real-world environment. To avoid such pitfalls, proper surface preparation is necessary before conducting any adhesion test.

Conclusion

Surface preparation plays a pivotal role in the accuracy and reliability of adhesion testing. Without proper preparation, even high-quality testing equipment like the adhesion tester cannot provide valid results. Cleaning, mechanical abrasion, and chemical etching are essential methods to ensure that the surface is ready for testing, offering true insight into the performance of the coating.

For businesses looking for dependable adhesion testing solutions, POWER BLAST Workshop Equipment Trading LLC is a trusted name, offering high-quality adhesion testers and expert support for industrial applications. Their commitment to quality ensures that you get the most accurate results for your adhesion testing needs.