In the world of industrial painting and coating, precision and efficiency are paramount. The use of quality equipment can significantly impact the outcome of a project. Among the essential tools for achieving a high-quality finish are spray gun tips and tip guards. These components play a crucial role in ensuring accurate application, safety, and overall efficiency. In this blog, we’ll explore the benefits of using Tips & Tip Guard in spray painting and coating applications.

Introduction to Tips and Tip Guards

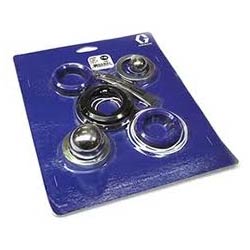

Spray gun tips are the small, replaceable components at the end of a spray gun nozzle that determine the spray pattern, flow rate, and atomization of the coating material. Tip guards, also known as spray guards or nozzles guards, are protective devices that surround the spray tip, providing safety and enhancing performance. Together, they form a vital part of the spraying process, affecting both the quality of the finish and the ease of application.

Key Benefits of Using Tips and Tip Guards

Enhanced Precision and Control

One of the primary benefits of using high-quality spray tips is the enhanced precision they offer. Different tips are designed to create specific spray patterns and control the flow rate of the material. This allows for greater control over the application, ensuring that coatings are applied evenly and accurately. Whether you need a fine mist for delicate surfaces or a wider spray for larger areas, the right tip can make all the difference.

Improved Efficiency and Productivity

Using the appropriate spray tip and tip guard can significantly improve efficiency and productivity. Properly matched tips and guards ensure optimal atomization of the coating material, reducing overspray and material wastage. This not only saves time but also lowers costs by minimizing the amount of paint or coating needed. Additionally, efficient spraying reduces the need for touch-ups and rework, further enhancing productivity.

Safety and Protection

Tip guards are essential for safety in spray painting operations. They provide a barrier between the operator and the high-pressure spray, reducing the risk of accidental injuries. Moreover, tip guards protect the spray tip from damage, ensuring consistent performance and extending the lifespan of the equipment. By preventing accidental contact with the tip, tip guards also help maintain a clean and uncontaminated spray pattern.

Consistency and Quality of Finish

Achieving a consistent, high-quality finish is crucial in industrial painting and coating. Spray tips and tip guards play a vital role in ensuring that the coating material is applied uniformly across the surface. Consistency in the spray pattern results in a smooth, even finish without streaks or uneven coverage. This is particularly important in industries where appearance and durability are critical, such as automotive, aerospace, and construction.

Conclusion

Using the right tips and tip guards in spray painting and coating applications offers numerous benefits, including enhanced precision, improved efficiency, safety, consistency, versatility, and extended equipment lifespan. At POWER BLAST Workshop Equipment Trading LLC, we provide a wide range of high-quality tips and tip guards designed to meet your industrial needs. Contact us today to learn more about our products and how we can help you achieve superior results in your projects.